Warp knitted PP geogrid/PET geogrid/steel plastic geogrid ultrasonic welding machine YXGC-6000

1.Equipment Introduction:

The production line is used to automatically knit and weld two kinds of strips.The supporting material of coal-mine roof which is used when exploiting mines;The steel-plastic complex net is used to reinforce the road basement and embankment.

Equipment Features:

1.PLC control system.

2.The transducer is the Germany piezoelectric ceramics ,the mold is made of aluminium alloy from USA

3.The pneumatic adopts the Airtac Material.

4.Use the supersonic design and welding depth establishment .

5.The intension between 20KN-200KN;

6.The mining geogrid size:40x40mm,50x50mm, 65X65mm

2.Characteristics

1. the vertical and horizontal strips are welded by high-frequency ultrasonic welding at the intersections ,the environment temperature could vary between -20 to 40

2. the number of the steel wire of one single strip is more than 9 or designed as the customer’ requests.

3. the intension of one single strip ≥4000N,the insulation resistance of the surfaces of one single strip ≥1000MΩ.

3.Equipment Parameters:

Item | Specification | Item | Specification | No.of welding heads | 24 | The whole machine welding width | 6m | Max power(KW) | 40 | Volume of air pressure | 0.2~0.3m³ | Size of the equipment(L*W*H)(m) | 7.0*8.0*2.2 | Transverse weld spacing | 40mm, 50mm, 65mm | Rated input voltage | AC380V 50-60HZ | The longitudinal weld spacing | 40mm, 50mm, 65mm | Rated input pressure | 0.6~0.8MPa | Daily output | 2000~3000 | |

|

4.Our advantages:

1.Technician are available to go to the abroad to make Installation and commissioning and supply technology support .

2.Generator have one year warranty and pneumatic parts have six month warranty.and provide all the accessories parts lifetime.

3.OEM or ODM are accepted

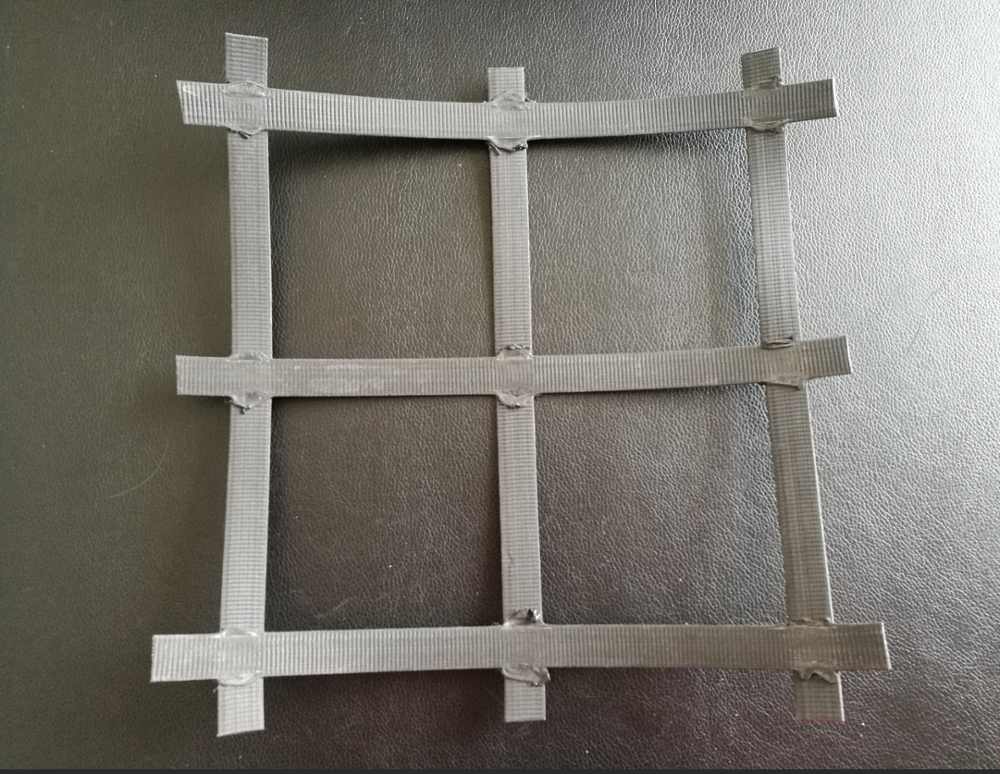

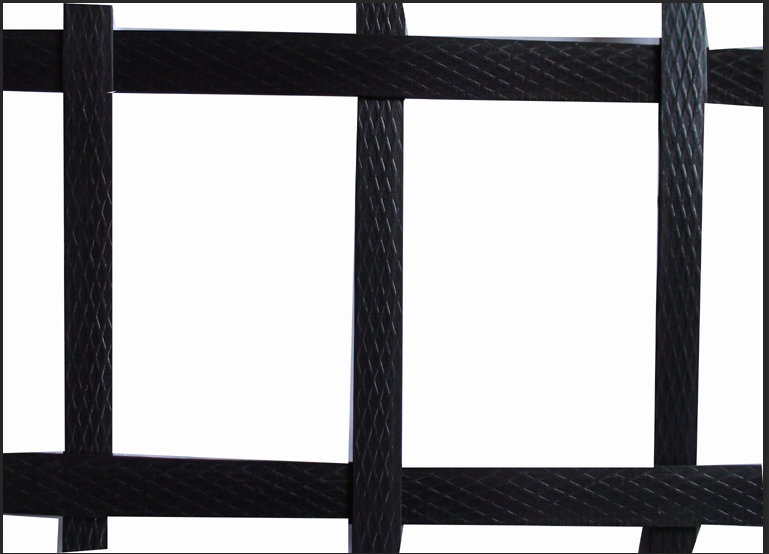

5.Products