PE PP Sheet Extruder Line

Equipment Introduction:

YX120/30 plastic sheet production line is designed and manufactured on the basis of absorbing domestic and foreign advanced technology. It’s specially for the production of PP, PE and PS sheets. This production line consists of 120/30 single screw extruder, mold of machine head, three-roll calender, Conveying and Edge-cutting Device, traction device, electric controlling cabinet and other components. The equipment has the advantages of fully automation, stable working performance, high output and low cost. It’s your ideal choice to invest in plastic products.

Equipment Feature:

1. Driving power of host engine is 110KW, AC engine, Frequency Control;

2. The gears are made of special alloy steel being carburized and quenched, and the gears are being grinded meticulously. External circulation and powerful cooling system. The whole gearbox is dedicated speed-reduction device which is long duration, low noise and low energy-consuming;

3. Screw material is 38CrMoAl high-quality alloy steel with nitridation treatment. Nitrogenization depth is 0.4-0.7mm, and the screw diameter is 120mm;

4. Barrel is made of 38CrMoAl high-quality alloy steel with nitridation treatment, Aluminum casting and electricity heating, 7 sets of cooling blower fans;

5. The Hopper is made of high quality stainless steel;

6. Temperature-controlling meter adopts RKC product; the Contactor, Relay and Power Indicator all adopt CHINT electric appliance; the Frequency Converter adopts Zhengxuan Product;

7. Special Hanger-pattern head mold, made of high quality steel special for molds;

8. Calender roll ( mirror polishing treatment ), 3 pieces. The rolls adopt single-channel design and inner circulation water. The machine frame is welded with superior structure steel and is equipped with height-adjustable trundle which could move forth and back along the track;

9. The heat exchanger is designed into three-loop pressure water circulation. The equipment is controlled by RKC temperature-controlling meter from Japan which with the protection function of water-shortage, over pressure and high temperature.

10. The idler is made of seamless steel tube and the surface is plated with chrome. There are10 pieces of carrier idlers;

11. The traction rolls are made of high-quality rubber. The traction power is 2.2 kw and the motor is designed with frequency control;

12. The machine cuts the strips in blades automatically when reaches the setting length.

Technical Parameter:

Item | Technical Parameter |

Power supply demand | 380V/3P/50Hz |

Raw material | PE PP |

Products | PE PP sheets |

Products Specification | Width:1200 mm Thickness:0.5-2mm |

Extrusion Output | 200-350kg/h |

Total Power | 180kw |

Dimension | 21000/2200/250 (mm) |

Equipment Weight | 15(ton) |

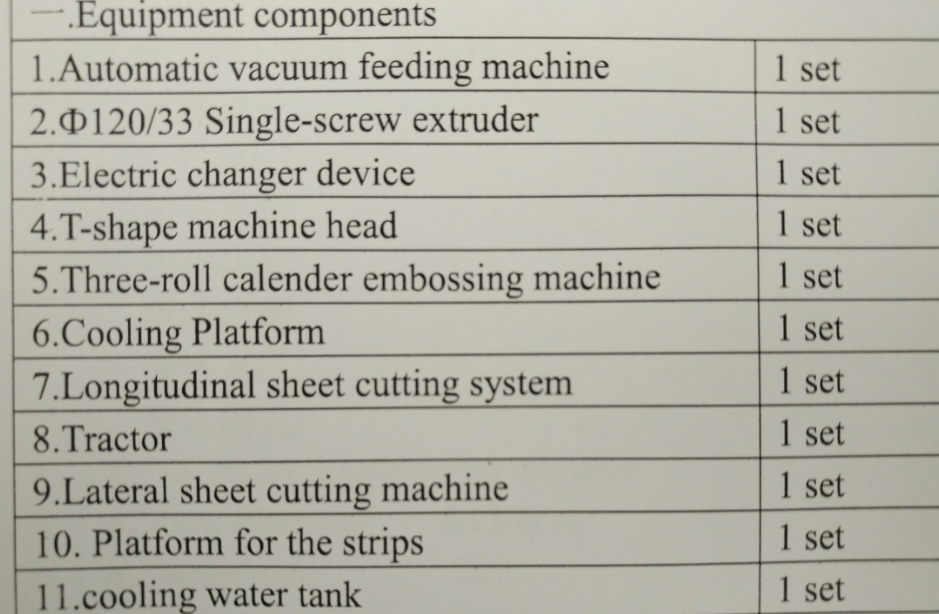

Machine components

![]()

![]()

![]()